The Christmas break saw me very busy with tasks other than amp building. So the new SET is a little behind schedule. In spite of it supposedly being a “quiet” Christmas with just immediate family, I ended up tackling several small projects which I had been putting off and I helped my daughter move. And of course I was back at work this week as well. Now that doesn’t mean that I got nothing accomplished, it just means that things are progressing slower than anticipated. This is where I’m at:

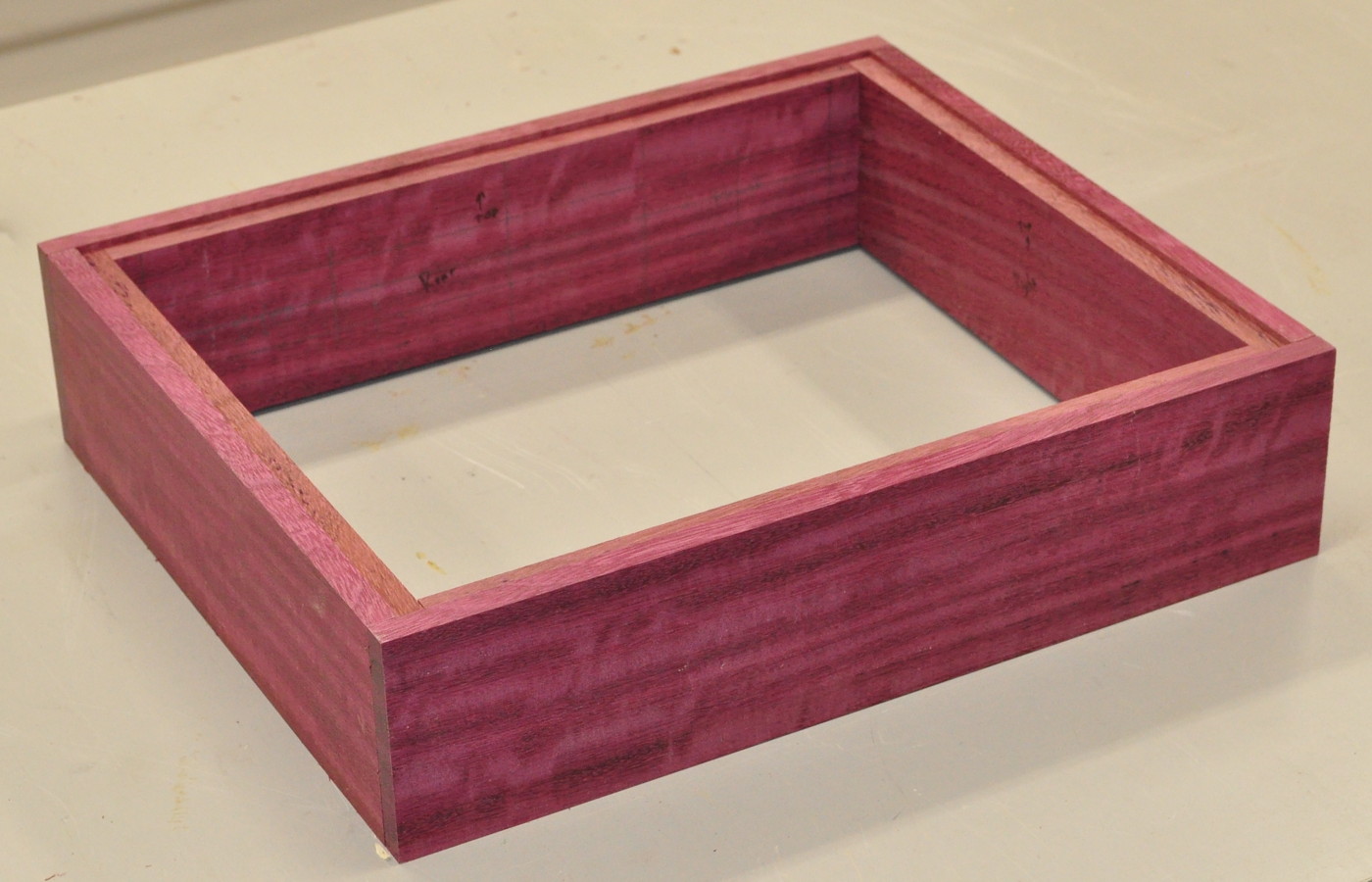

The wood is cut and all the basic joints, and top/bottom plate reliefs, are cut. From this point I need to complete the layouts for all the penetrations, make the openings, and rout reliefs for backside metal attachment. After all that is complete, I’ll glue up the chassis and finish the final shaping and sanding. Once the chassis is completed “in the raw”, I will begin cutting metal. In this case both copper and aluminum plate.

This finally is beginning to feel like a real project as opposed to just an idea. I was beginning to feel like I was stringing folks along on this new amp. Then I realized that it was only back in August when I completed the 6CY7 Zebrawood V2 amplifier. So I’ve only been cogitating on this new project for about four months. For me that’s almost no time at all.

Also, while digging around in my stash, I found this forgotten pair of 6AS7s sitting on a shelf with a bunch of industrial 6080 tubes.

One of these should look really good in the center of the new amp. This gives me a new impetus to get things moving again. More progress should be coming soon.

It’s taken a while but I have managed to find a piece of silky oak to fabricate the base with. Found someone on Facebook who also makes benchtops out of various timber and has plenty to spare of timber to go round but only had this last piece of the silky oak. I should practice on a piece of pine first though as I had to pay a bit for it and my skill in working with timber does not yet exist!

Also have ordered the power transformer and main choke from mouser. I think they are supplied from China or Hong Kong in this region but unsure. My local Hammond supplier doesn’t have these in stock last I checked. Still thinking about the output transformers and the cost. The absence of local transformer options is sorely missed.

I do like Australian silky oak. Do you know if yours in northern (Cardwellia sublimis) or southern (Grevillea robusta)? Both are nice but I think the souther variety is easier to work IMHO.

The builder I bought the plank off wasn’t sure but it came from a local tree so I suspect the Grevillia which you see growing in parks and roadside plantings locally. It is a bit rough sawn so I won’t know how good it will look until sanded and oiled. I can see it has a light speckle which might show up nice.

A house built in the 1950s I lived in for a while had window and door frames made from silky oak. The previous owners stripped the paint to reveal quite rich grain and flare. From what I read ( see http://timbersalesbrisbane.com.au/australian-species/northern-silky-oak/ ) the Cardwellia was more popular for this purpose and wooden furniture of this and earlier periods. I am not familiar with this tree though.

I look forward to seeing some pictures when you get the chassis completed.

The 6AS7GA I bought some time back from a fellow in Melbourne are GE USA. They look fine almost pristine but no way of knowing how good they will be. These are just the cylindrical shape. I bought an additional pair advertised as 6as7 but are 6N13P which I think are Chinese and have the same shape as yours above. Have you done any prototyping of the driver and power stages together yet?

When I was working on the 6336 I prototyped the 6AS7/6080 power stage using the 2.5kΩ outputs from that project. I tried a GE 6AS7 (ST16 bottle shape) and a JAN 6080WC made by Philips ECC (in the USA, T12 shape). Both worked well. I have not prototyped the whole chain together yet, but the individual pieces have all been built and tested. The driver is the same one used in the 6336 amplifier with excellent results.

Looking promising Matt. Very neat timber joins—are any special tools needed for those? This may be helpful for those intending to follow Hopefully me at some stage 🙂 I too started back at work last week but luckily took a couple weeks off in November for a driving holiday up north while there was zero covid cases reported. Christmas time I had my hands full fixing a leaking toilet. Two more to go before they start leaking.

Those are actually just simple rabbet joints on the corners with the overlaps on the front and back plates. Nothing special required. I cut them on the table saw with a dodo head installed. Once glued they are incredibly strong.