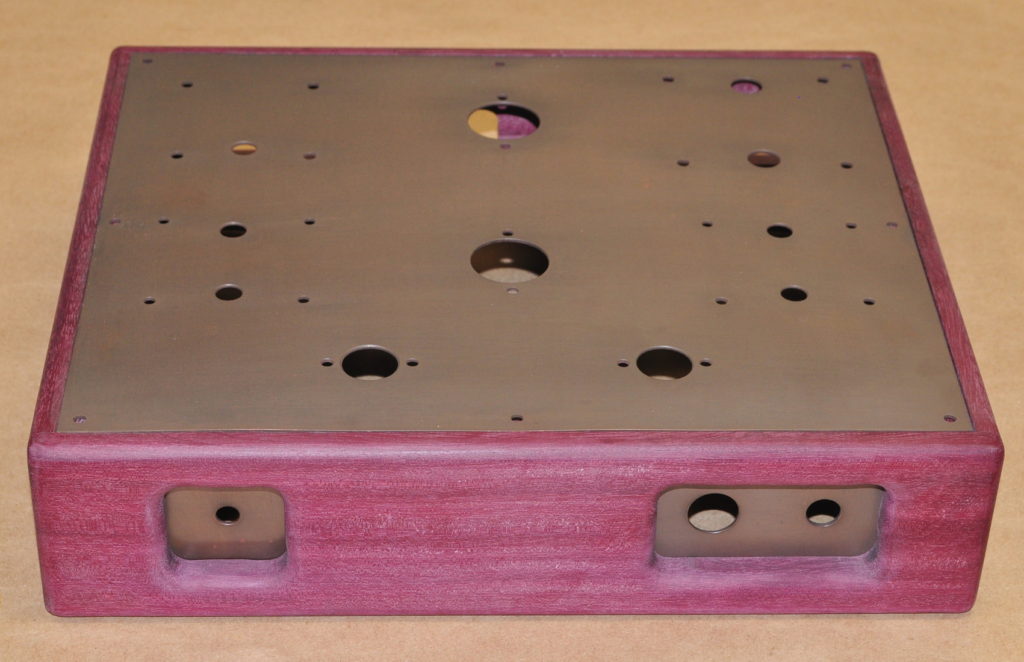

It’s been a tense couple of days waiting for the patina to set on the 6AS7 SET top plate. But I just placed the copper on the chassis and it looks great!

Without further ado, here’s how it looks now.

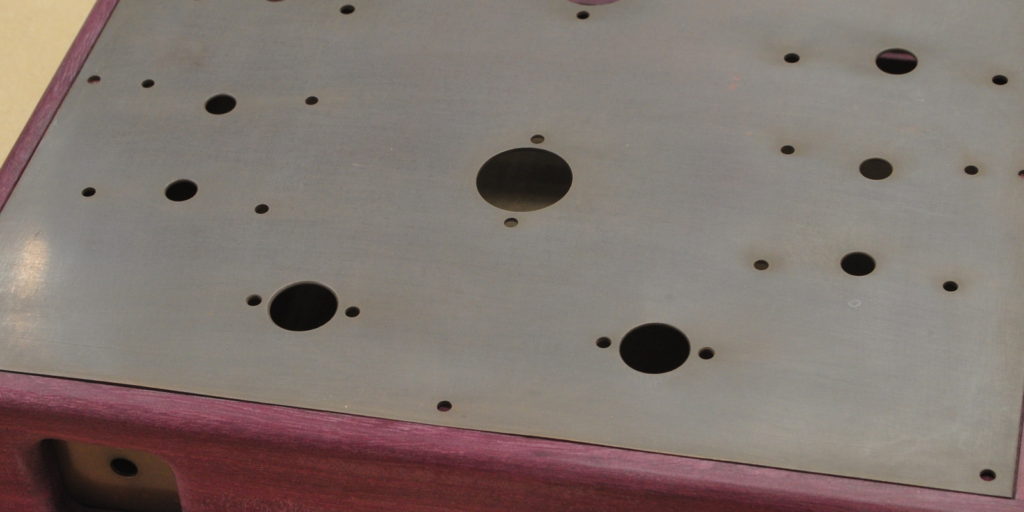

This looks much better that the first attempt. It is much more even yet still retains that aged “tarnished penny” look. The photography really doesn’t do it justice. I really don’t have the best lighting in my shop for taking pictures. Here is a closeup of the top to try and get a better feeling for the tone of the metal.

The tone really changes with angle and lighting. The starkness of the purple is still a little bright, but over the next couple of years the overall tone of the wood will darken. Then the match should be exceptional. I’m very happy with how this is coming together.

Unfortunately, temperatures have fallen again and it’s far too cold to apply finish. It looks like this may have to wait a little while until we get some warmer weather. I’m going to get the chassis for the triode test jig glued up and ready for finish. Then I’ll be ready to go on both chassis when the temperature is right.

Here’s another way to patina

https://sculptnouveau.com/products/traditional-brown-patinas

Quick question:

Is it possible to use a small electric heater in your shop? In the past I have used them to warm up cold indoor work areas.

I have two small milk house heaters (1500W each) that I can use. However, they are really only good for about 10° to 15° at best. There is just too much air leakage in the shop to do any better. I should get some warmer weather later in the week.

My preferred wood glue has a chalk temperature of 55°F (≈13°C) so I should be able to get the glue up done today. But the oil finish I use has a minimum application & set temperature of 60°F (≈15°C) so that will probably have to wait for warmer weather.