I’ve been catching up on all my spring chores and managed to steal a couple of hours in the shop this morning. The Source Selector Unit chassis is now all sanded. I also took the time to cut and fit the aluminum for the top and bottom plates. Now my attention will turn to getting all the holes laid out and drilled on the aluminum.

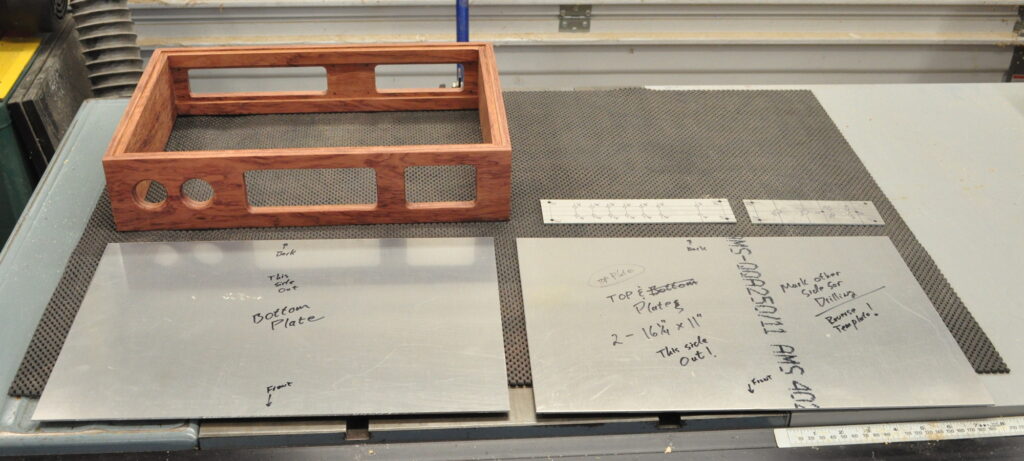

I like this chassis more and more every time I see it. With all the sanding complete it finally feels like good progress is being made. Here’s the freshly sanded chassis along with all the aluminum plates I need to get finished.

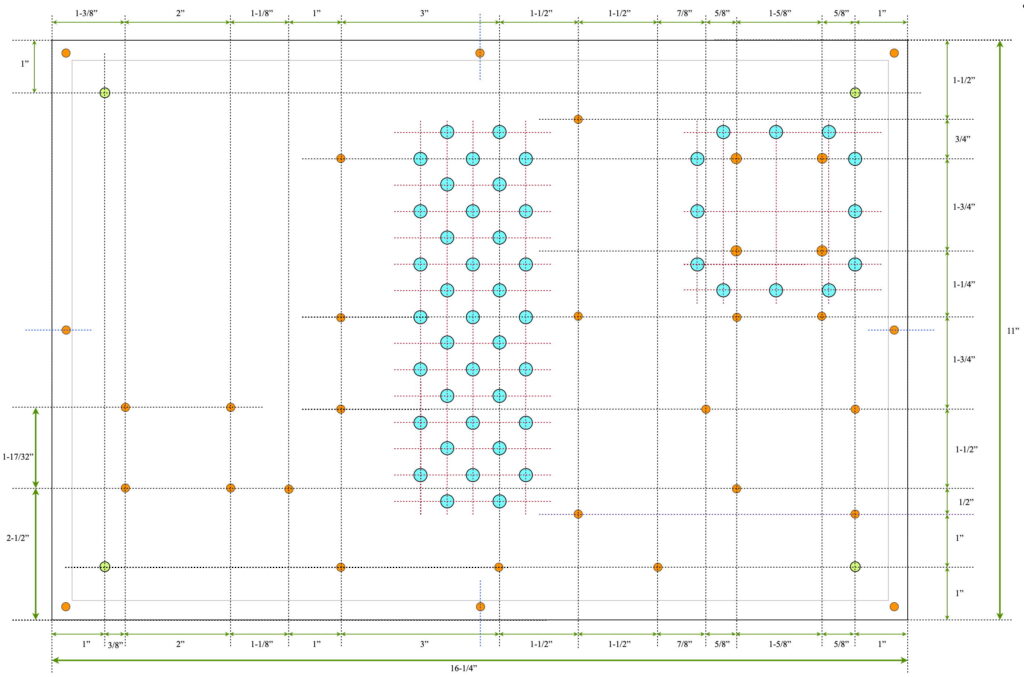

It’s important to remember that this is not all the metal for the amp. There are some pieces of angle bracket which haven’t been formed yet. And there is a 3″ by 8″ (7.6cm by 20.3cm) aluminum plate which will hold the tubes and most of the components. So I still have some cutting to do and a lot of layout before I get to drilling. Just for reference, here is the hole layout just for the bottom plate.

With some luck I’ll get things finished and start layout in the next couple of days. And once everything is drilled and ready, then it will be finishing time for both the wood chassis and the top and back plates.

As always, questions and comments are welcome.

Do you have a shear there in the workshop or do you cut the pieces another way?

Actually I use a fixed table saw with a sliding table. You can read all about it here: https://www.cascadetubes.com/2023/05/04/about-that-metal-work/