As it turns out, there is a crew working on painting the exterior of my house today. Since I can’t work on many of my outdoor projects around the house, I thought I’d take the opportunity to get a little done on the source selector unit.

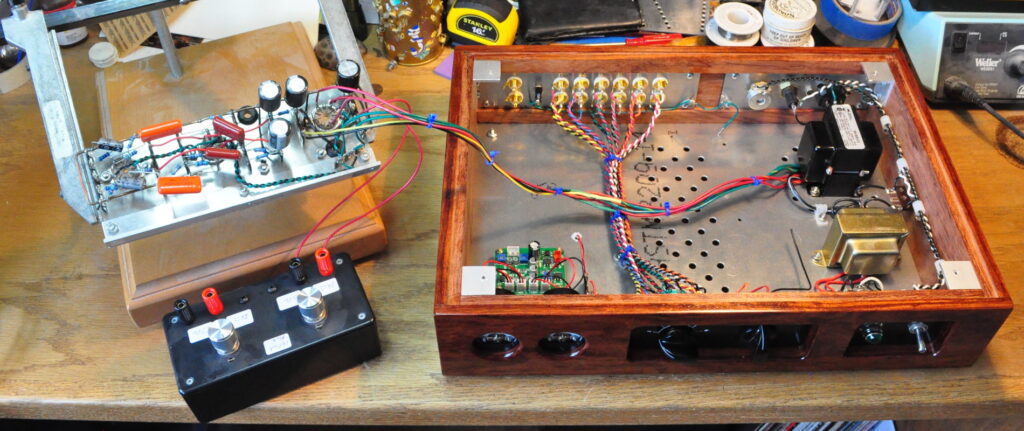

Just for a reminder, this is how I left the project on my work desk when I got busy.

With the exception that the final dropping resistor was installed and the signal inputs on the gain stage were grounded.

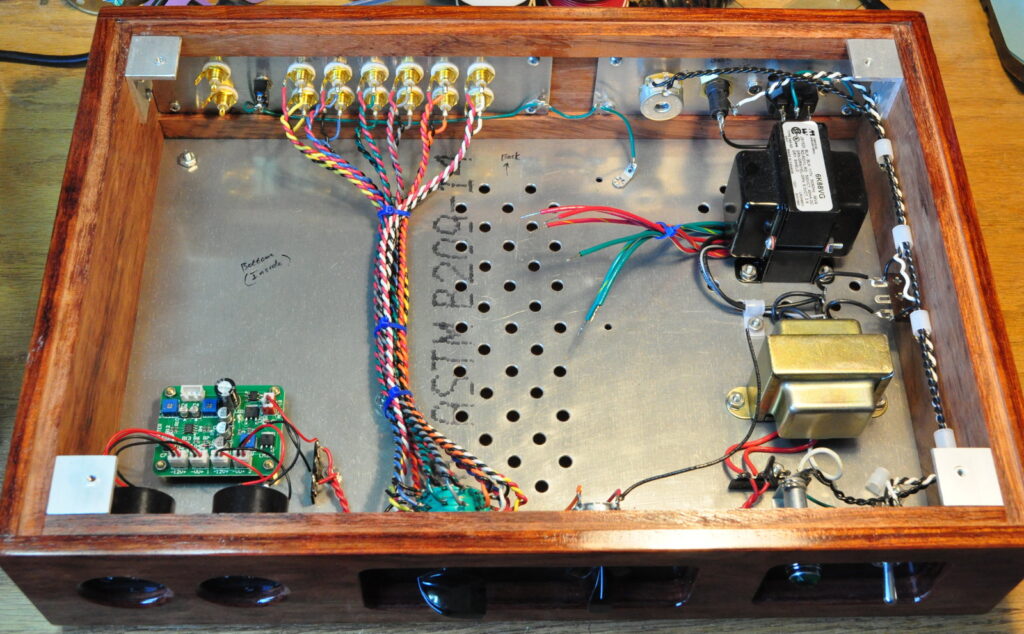

The first steps were to remove the long power pigtail connecting the tube assembly to the main power transformer. So I removed all the temporary connections from the tube assembly and installed the wires for the signal outputs. I also trimmed the power transformer leads to the proper length and tinned all the ends. The chassis is ready to go now. Here’s how it looks.

And while admiring my minor handy work I came to a realization. In my haste to get to work on the vacuum tube assembly, I never gave the input selector switch a proper electrical checkout. If there was a problem, it would be much easier to address at this stage rather than after everything is installed.

So I took a break from my assembly, broke out a little test equipment, and went to work. This is not really an involved or difficult test. It’s basically a continuity check to make sure signals are going where they are supposed to and not where their not supposed to. Here is my simple setup.

This test is simply running a signal through the various inputs (all twelve) and making sure that the signal appears only when it is selected and that it only goes to the appropriate channel. This test actually took less time than setting up the test equipment. There were no problems. However, if there were, I was prepared to tackle them before proceeding any further.

This type of serial “build up” testing is actually a very good idea. Catching and correcting minor problems early means less problems at initial power up and during system testing. It also, at least for me, means a much more satisfying experience. I’ve had some less than satisfying experiences in the past.

With some luck, I’ll get the final assembly completed while the painting crew is still working. When the assembly is complete, I’ll let everyone see how it looks.

As always, questions and comments are welcome.

Pingback: It’s Truly Amazing | Cascade Tubes