Please read the post “That Didn’t Go Well!” before following the power supply change detailed in the later half of this post.

Sometimes a design which seems fine at first can later exhibit some marginal behavior. This exact issue recently reared its head with the design of the 6L6 “Spalted Alder” amplifier.

When I first started on the design of this amplifier, I did not prototype the power supply. Instead I looked at the design data and, based on my experience with the 6AS7 “Purpleheart” SET power supply, decided that the GZ34/5AR4 rectifier would work without problems. My oversight was in not noting the significantly higher rectifier plate voltages in the new design and taking appropriate precautions.

When first put into use, with the GZ34 rectifier I had on hand, the amp worked flawlessly. And continued to do so for many months. That’s when things started to go sideways. One evening the right 6L6 failed by arcing within the tube. It took a minute to notice and get across the room to shut down the amp. I replaced the tube, powered up the amp and everything seemed fine. The amp continued to operate apparently normally for a couple of more weeks, operating for five to six hours a day.

Then, after a couple of weeks, the GZ34 started to randomly arc at startup. Usually it was just one simple pop at startup and then the amp would function normally. I naturally assumed that the GZ34 was on it’s way out, so I ordered a replacement (I didn’t have any on hand) and inserted a 5U4GB until the replacement arrived. When I inserted the new GZ34 and powered up the amp, the new rectifier instantly started arcing and popping with a truly impressive internal light show. I immediately powered down the amp. This was going to require some investigation.

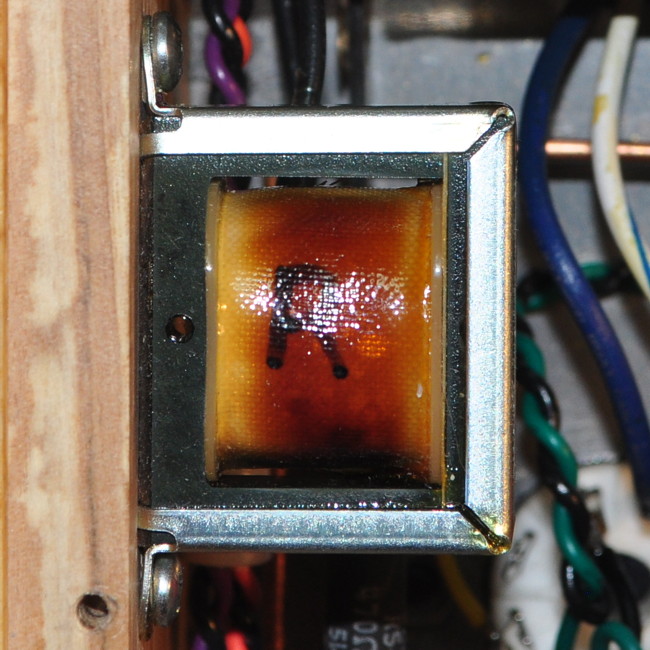

Upon opening up the amp, the first apparent problem was the 2H choke on the right channel power stage B+ filter. The choke showed significant discoloration. Here’s how it looked.

When I checked the choke it only measured a 6mH and had a series resistance of 6Ω. The choke had melted. I can only assume that this happened when the 6L6 failed by arcing over. Because the choke still had conductivity, the power stage could behave normally with just a little less B+ filtering. So the first step was replacing this choke.

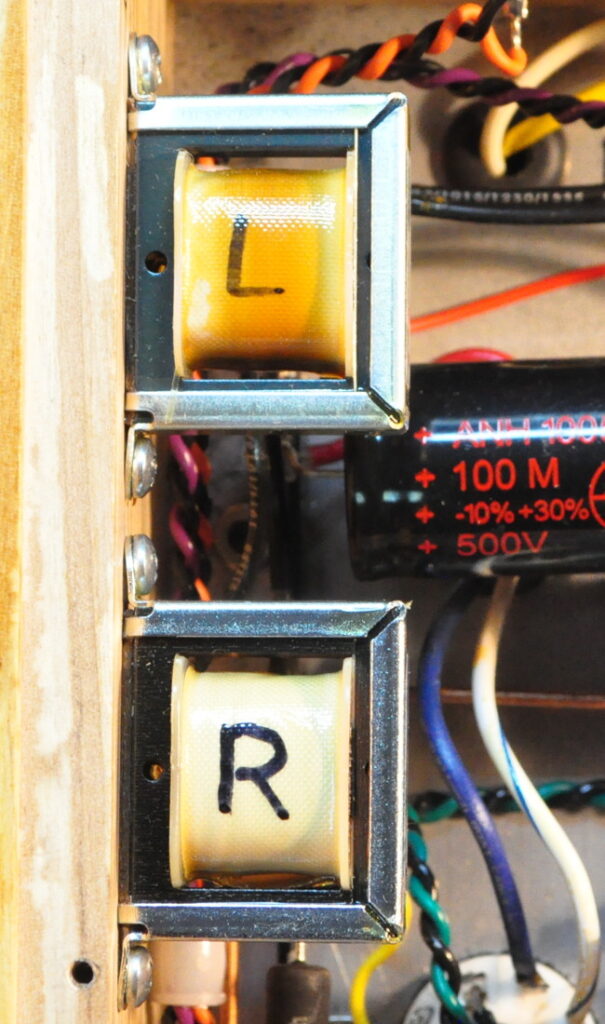

The left channel choke also showed some signs of overheating but still checked out ok. I decided to leave it alone. This amp has had a series of tubes in it for testing and I don’t know if one of them was operating with significantly more plate current. I know that a couple of the used 6L6s I tried in the amp behaved poorly and were discarded. Here is the new choke installed.

From this picture you can get a feel for the level of discoloration on the left channel filter choke. As I said, it shows signs of overheating but checked out within specification so I left it alone.

Following this repair, I meticulously checked every other component in the power supply. Everything checked out well within specification which left me in a quandary. The amp initially worked as designed and only had problems after tube failures. But I had repaired those failures and there was no reason that the shorted choke would cause problems with the new GZ34. So why had the new rectifier so quickly went to the great gig in the sky?

In an attempt to answer my question I went back to the specifications for the GZ34. The open circuit secondary voltage on the Edcor XPWR178 is about 350v per leg. According to the specification sheet, the recommended series plate resistance at this voltage is 105Ω with a 40µf first filter capacitor. My power supply uses a 30µf capacitor so this requirement could be slackened somewhat, but not a tremendous amount. The effective series resistance of the transformer by itself is only approximately 30Ω per leg. This is the genesis of my problems. Every other failure can be traced back to the blown 6L6 which obviously weakened the already stressed rectifier and the insufficient rectifier plate resistance.

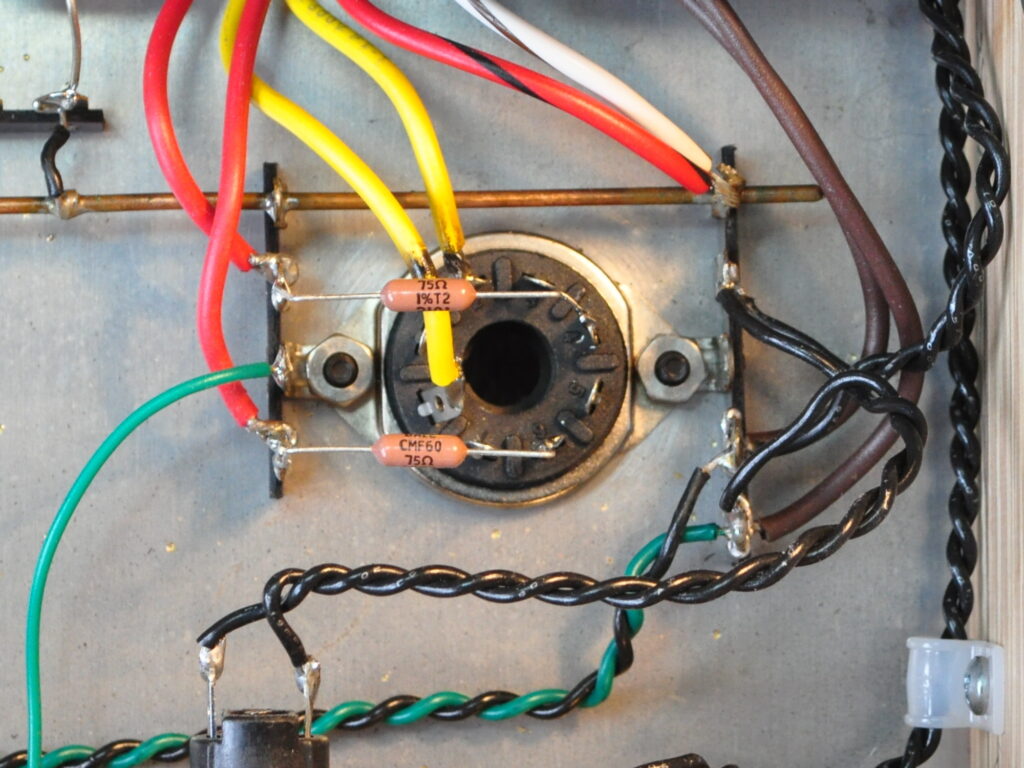

So I needed 75Ω to get back to the recommended series resistance. I had available we some 75Ω/1W resistors. With the smaller first capacitor this will provide some additional protection and won’t cause more than a few volts of additional drop in the final supply B+ voltage.

So the transformer / rectifier wiring was modified to include these increased plate resistors. Heres how the new configuration looks.

I simply moved the secondary leads over to a couple of open lugs on the terminal strip and inserted the two resistors between the terminal lugs and the rectifier socket. This is a simple wiring change which doesn’t even require any mechanical modifications.

I am recommending this change for anyone who has built (or is planning on building) this design. I have already made the necessary modifications to the main project page.

This whole episode serves to illustrate the pitfalls associated with the “build it and see” approach to design and build. I clearly made a major design error by not including the necessary rectifier plate resistance. This is an error I fully intend to avoid in the future. However, because, just by chance, I had a stronger than normal tube, the design worked for some time before problems became apparent. And now there are some other people out there with this very same issue. I feel bad about this.

So if you’ve built this amp please make this modification. In the future I’ll try to be a little more methodical in my design practices.

As always, questions and comments are welcome.

Thanks Matt, I really enjoy your posts an I’ve learned a lot from you. I never trust GZ34s especially the newer products, for this reason I normally use 5U4 and recently I replaced the 6336 amp design with 5U4 for lower B+. Whenever I use a GZ34, I always add two UF4007 diodes in series with two plates to prevent any damage to other parts in the case of GZ34 internal shorts.

I have never personally had a hard short in a GZ34. I have had arcing but only when I had ignored the plate resistance requirement. Adding solid state diodes in series with the vacuum tube rectifier plates actually does nothing. Even if the tube arcs over, the solid state diode drop is so low that the effects on the downstream components are the same. Meeting the series plate resistance requirement is always a better option than attempting to anticipate a particular failure mode and inserting solid state devices in the design.

Of course meeting the minimum series impedance of tube rectifier plate should be the initial concern, but even with that I’ve seen newer GZ34 products short inside!

Using series diode with each plate will prevent the AC entering HT circuit and will protect the overload of PT secondaries and chokes and also protect the filter caps from reverse voltage.

Using additional redundant components to correct initial design flaws is bad design practice. If the power supply design is done correctly, such measures are never necessary. I would never condone such design practices in my work or the work of anyone on my Engineering team.

Pingback: That Didn’t Go Well! | Cascade Tubes

Pingback: Sneaky Capacitor Failure | Cascade Tubes

Thank you very much for taking the time to write this.

What do you say about the practice of connecting a diode in series between each leg of the PT HT secondary and the rectifier plate, and a thermistor between the HT CT and the first capacitor’s negative leg? Although with those two resistors, a thermistor may not be needed.

More power.

The use of discrete diodes in series with the rectifier plate leads does nothing. It is an attempt to offset a low probability failure mode in the rectifier. It’s bad design practice. The same is true of the PTC thermistor in the center tap of the transformer. Thermistors are designed as feedback sources in control loops. There is no need to attempt to insert a control loop into the secondary side of a power transformer. In the best case scenario it has very little effect, in the worst case scenario it can lead to power supply instability.

Proper design practice calls for adjusting the equivalent series winding resistance to ensure the repetitive peak plate current is not excessive. Which is what I’ve done with the inclusion of the two 75Ω resistors.

Thanks for the update. I love this amp!!! I just upgraded to PSvane Horizon tubes and like the sound better than the JJ’s. They seem to be a little more detailed (or better on the top end). I am also trying some different capacitors for the .1uF coupling caps. Bevenbi silver foil from ebay since I didn’t want to spluge for the mundorf. I admit I’m not sure if there is a difference between these and the orange drops I had in there which seem very good to me. Is 400V enough on these??

I need to add some resistors to mine. Can I use metal film or should I order something else? I thought there was some reason not to use the metal film in power circuits but I can’t remember.

A 400v rating on the coupling caps is marginal in this design. I used the 600V CDE Series 716 orange drops (CDE716P600V 104J 1932) in my build. I specifically went with the 600V version because I don’t believe that a 400v rating is sufficient at this B+ level.

Metal film resistors are fine. Just make sure the power ratings are sufficient for the installation.

Thanks, I thought 400 volts was marginal I get a little confused if the grid voltage is negative or not I guess I could measure the voltage across the cap. 350 volts is less marginal than 382 volts across that cap.

Grids are at 0v in self biased designs. More importantly is that the plates are at B+ before the tubes start to conduct. So depending on how fast the B+ comes up and how fast the tubes start to conduct the coupling capacitors can see up to the full B+ voltage across them.

Update completed. The voltage at the signal stage is now around 335 and the power stage 380. What do you think about changing the 20k

resistor to get closer to 350 in the signal stage?

Not necessary. The 335v B+ to the signal stage will work just fine.

Matt, Thanks for taking the time to write and include photos. I am so excited to see new content in the blog!