I have witnessed a lot of electrolytic capacitor failures. Most of these failures have occurred from improper wiring polarity or a significant over voltage condition. They generally involve an explosive emptying of the capacitor shell. These failures usually leave a smoking husk of a component and a spray of foil bits, dielectric insulation, and liquid electrolyte spewed across the circuit, chassis, and sometimes, the test technician. But recently I came across a much different failure. One which seemed to be specially concocted to sneak by without notice.

I discovered this failure during the recent repair of the 6L6 “Spalted Alder” Amp after I had a 6L6 power tube fail during operation. At first, I did not realize that the capacitor had failed. As I said then, in the post A Slight Revision to the 6L6 “Spalted Alder” Amp, “I meticulously checked every other component in the power supply“ (emphasis added). What I did not do was check all the other amp components as well. Luckily, before sealing up the chassis, I noticed something interesting.

The bottom plate to the chassis was sitting on top of the Source Selection Preamp in my office. When I looked at it, I noticed something interesting. In the light from my office window an anomaly was visible.

This was something that clearly shouldn’t have been there. Only the volume control is in that corner of the amp and there is nothing in a volume potentiometer which could have deposited this on the cassis base plate. So I started to look around to see if I could identify the source. It didn’t take long.

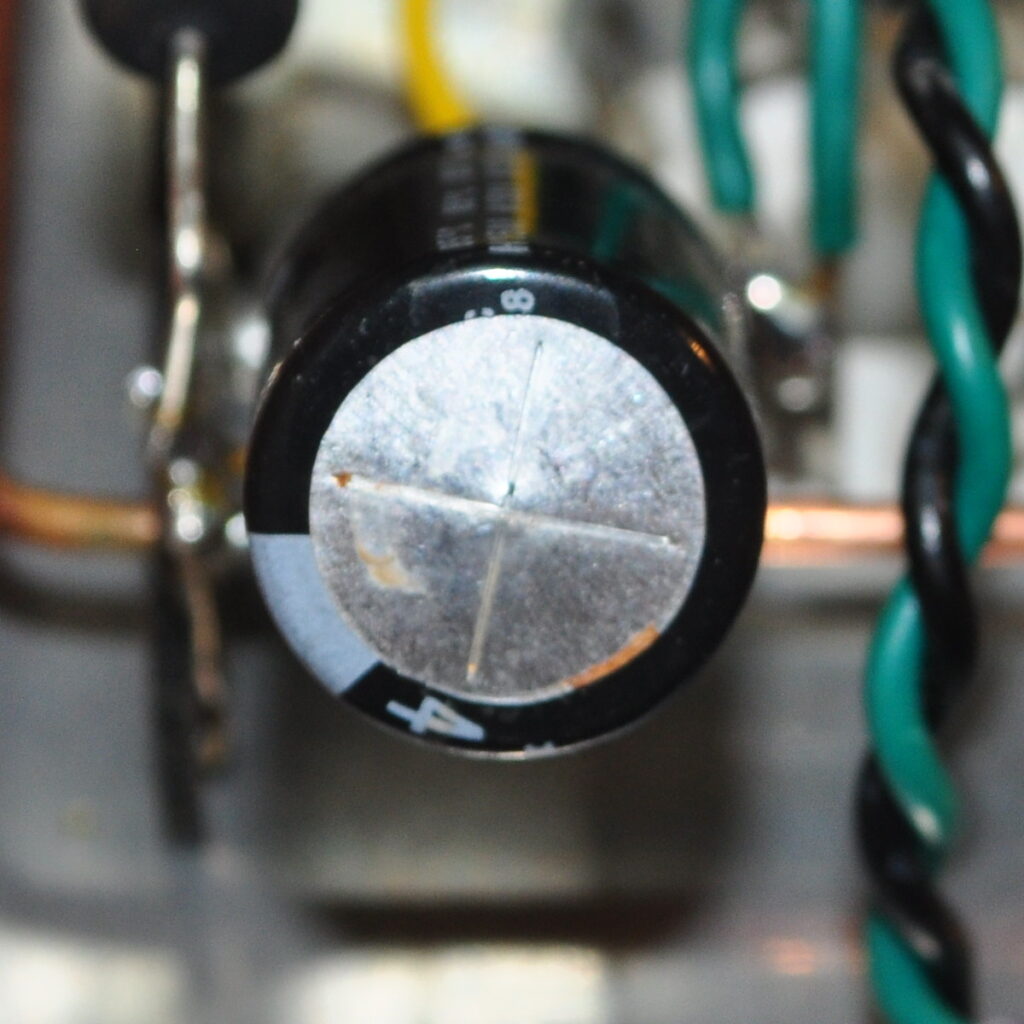

A few inches away was the top of the right channel cathode bypass capacitor. This is a 470µf / 50V electrolytic capacitor across the cathode bypass resistor. Clearly when the right channel 6L6 power tube failed, the current spikes drove the cathode voltage far too high for this capacitor to survive. But here’s the interesting part. Below is a picture of the top of the failed capacitor.

There is a small bit of dried electrolyte at the end of the left hand vent slot and a small amount dried on the top of the can on the lower right. The capacitor did not open up and vent as is typical. When I ran my finger over the top of the capacitor I did feel a slight protrusion where the top had pushed out a little. This was especially evident when I compared it to the bypass capacitor from the other channel.

Strangely enough, this “failed” capacitor measured just slightly over 300µf when I tested it after removal. This was likely why I didn’t realize it had failed from the right channel bandwidth. It was still working after a fashion. In any event, it is never a good idea to leave such a component in place, so it was immediately replaced. Here is the repair of the right power channel cathode circuit.

This serves as a cautionary tail when doing amplifier repair. Don’t just use your eyes, but all your senses. And look at the schematic and see what else may have failed. Cascade failures are very common under circumstances such as these.

I am happy to report that the 6L6 Spalted Alder amplifier is back in operation and sounding fine. I have experienced no further rectifier problems and everything is back to normal.

As always, questions and comments are welcome.

Nice catch! Glad the amp is good to go again.