When I talked about designing the Dual Triode Test Jig in the “More on Tube Testing” post I mentioned an indulgence. Well the results are in.

The indulgence in question was having the main panel for the test jig professionally made. Normally I don’t do this. If I want to build something I simply layout the top plate, cut a piece of aluminum, and retire to my shop to drill holes and paint the final product. What made this time different was two factors.

First, the top plate for the test jig has a lot of connections and controls. Normally, I can leave my test jigs unlabeled and simply “remember” what’s what. On this jig however there is no way I could ever keep everything straight in my head so everything would have to be labeled. And, I decided that if labeling was required anyway, it should at least look nice.

The second factor was something I’ve wanted to try. There is a small company near me named Front Panel Express. They produce metal panels and enclosures and will do single or multiple units. But the really unique thing about Front Panel Express is that you can do the design process yourself with their own software. I’ve wanted to give them a try for a while now and this was an excellent opportunity.

The process is actually very simple. You just go to their website and download their Front Panel Designer software. They have Windows, MacOS, and Linux versions. I used the MacOS version. The software is free to download and use. Most of the features are fairly straight forward and they also have some videos on their website to get you started. I recommend that you do a couple of designs just to get used to using their software. They can also take graphics files for inclusion on your design but I didn’t use this option.

So the big question is how did they do. The answer: AWESOME!

Just so you can see how they did, I’ll start with the comparison. The first image is the graphic file produced by their software, which I shared before.

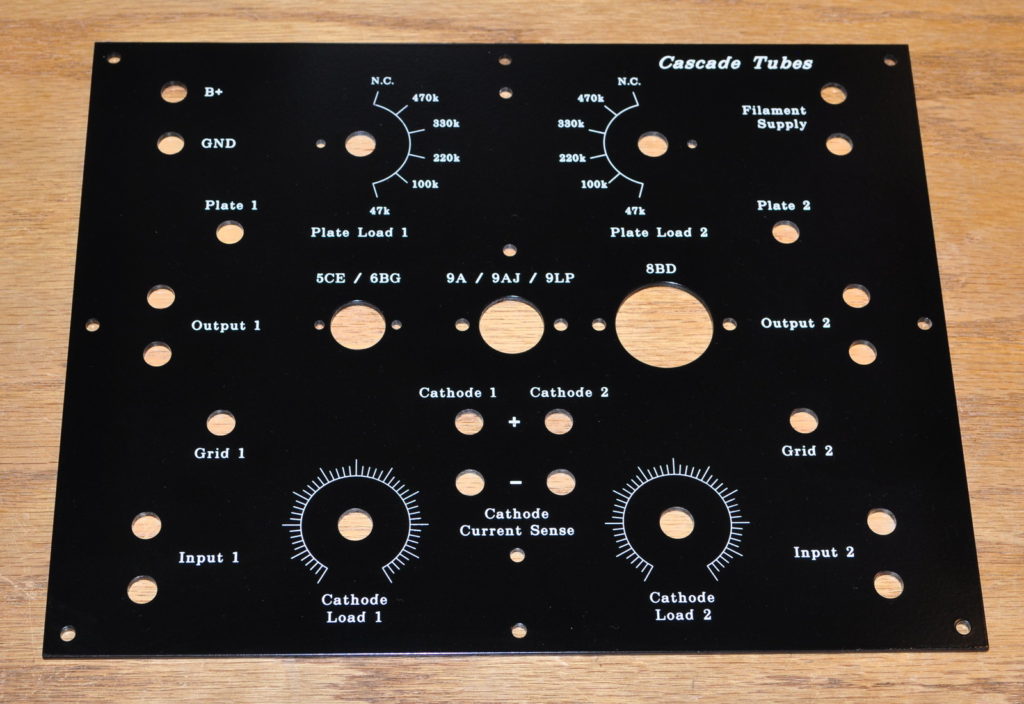

When I ordered the panel, I thought that if it looked as good as the graphic, I’d be happy. Well, this is the panel they sent back.

It is even better than I imagined. My photography does not do it the justice it deserves. The milling is perfect, the black powder coat is very even with a superb finish, the lettering is perfect without any overruns, and the placement of everything on the plate is exact. And because all the markings and lettering are engraved in the surface, the markings should stand up to heavy use. In and of itself, this is a very nice feature. It’s something which I could never reproduce in my home workshop.

Now I said before that this is not cheap. However it’s not really very expensive either. The plate above cost me $182.90 USD. When I think of the many hours it would have taken me just to produce the plate itself, to say nothing of the time to mark everything, this is a very reasonable price. And for an amplifier face where you wanted to include basic markings and scales, this would be a very reasonable thing to add to your project. I designed a representative face plate for a stereo amplifier and it came out to less than $80 USD. And one of the great things about their design software is a built in pricing function. At the click of a button it provides a detailed pricing list showing the incremental price of the materials, each hole and marking, and each detail. I used this function frequently while designing the plate to see what were the price drivers and making changes as I went.

Another great thing about this process was the timeline. I uploaded the design file from Front Panel Designer to their website and placed my order on December 9th. My finished plate shipped out to me on December 15th. That’s only five business days! I haven’t even finished sourcing all the materials for the test jig and the finished top plate is already in my hands.

As you can tell, I’m very pleased with how this turned out. And I cannot say enough good things about the service provided by Front Panel Express. I highly recommend that you download their software and try your hand at designing a plate for your next build. It could add a real touch of professionalism and polish to your finished project.

Yes, definitely looks “factory made”. And proves that often the packaging costs more than the electronics inside. Definitely something to look into for “top shelf” projects.