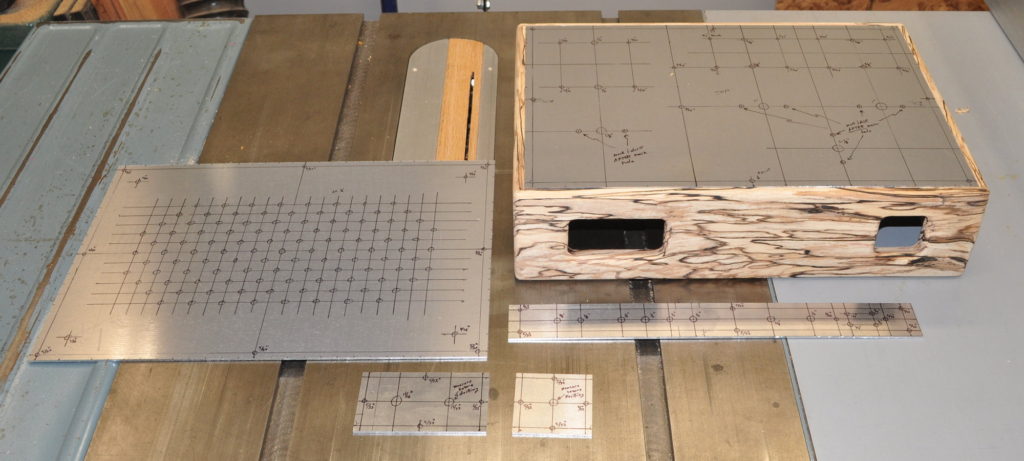

I have finally finished cutting and marking all the metal for the new amp. Now comes the long process of getting all the pieces drilled and finished.

Here’s all the metal appropriately marked with the top plate sitting on the chassis.

Most of this should be fairly straight forward. However, the venting in the bottom panel may take some time. That’s a fairly large number of 1/4″ (≈6mm) holes. More progress to come soon.

As always, questions and comments are welcome.

The clear wood color and the light grey aluminum gives it a “Nordic Design” feel. I find the combination very elegant. If you keep clear tones (including the potentiometer knob) on the whole chassis it will be an interesting change from your other amps with darker colors.

I can’t tell….do you put a clear layer on the metal (some use scotch tape) and mark up on that? Or just mark on the metal and clean later. Im lazy so I just sharpie on the plate. Punch centers. Drill away. Alcohol to the rescue. Then I use some alcohol to clean off the plate.

It depends.

One of my metal suppliers ships with a protective thin adhesive layer on the metal (clear). When I use this metal, I leave the film on the metal until I’m done with fitting and drilling. Then I just peal it off for a virgin mill finish on the metal.

However, when I buy locally, I tend to by from the cutoff/scrap bins at my local metal suppliers (much cheaper and I can use the odd size pieces). Typically this metal is bare mill finish. In this case I mark directly on the metal with sharpie. When everything is done I clean both sides with some isopropyl alcohol on a couple of cotton balls.

I tried the masking tape route once and it just seemed like more hassle than it was worth.

I’ve had good results using quality (not dollar store) masking tape. About the only way to go with the plastic project boxes I typically use.

I do use masking or drafting tape when I’m drilling or cutting plastic. It’s the only way my old eyes can see the markings.

Have you considered using Front Panel Express for this project? The wood base is deserving of factory made metalwork.

I thought about it, but I decided to do the top myself. And doing it myself allows me to make any minor adjustment to the top if the chassis is a little out of square or the boards decide to not remain perfectly straight after finishing.

I’m thinking about building a stackable integrated preamp with input selection, tone, and gain controls. That will definitely get a manufactured front plate.